Assistance for all stages of product development:

Design, mechanical and electro-mechanical planning, prototypes, conceptual and detailed designing, technical documentation drafting for CE marking.

Evaluation and preliminary validation of ideas

Technological Forecasting

Standardized TRIZ, Evolutionary Design

Patent research

Industrial Design, mechanical and electro-mechanical planning

Integrated Product Design

Industrialization, definition of equipment, production specifications, technologies

Regulations and Directives, assistance with product certification (CE)

Diagnosis and Energy Plans, Energy Efficiency Interventions

Planning, inspection and assistance with welding certifications (WPS-WPQR)

Partners network

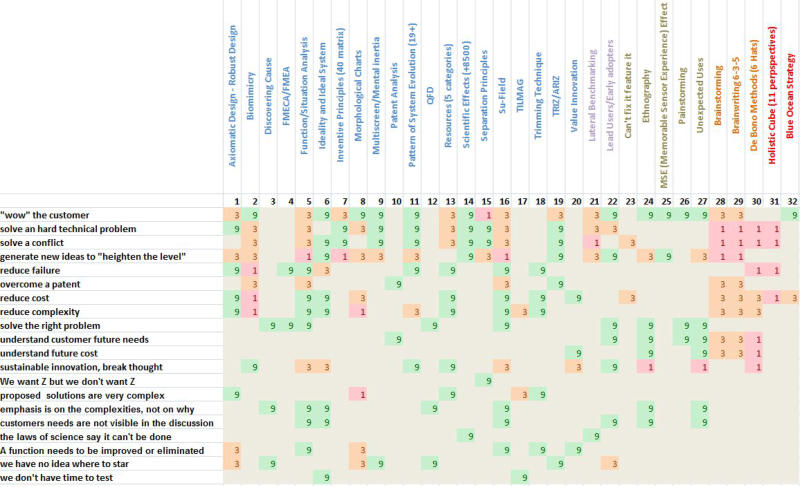

Systematic Innovation

The development of innovative product and process solutions can no longer rely on the intuition of the individual or the ability and experience of a few “enlightened” ones. More and more, the realization of an effective product requires not only intuition, taste or manufacturing skills but a complex and articulated system of integration of skills in increasingly wider sectors of knowledge. Just as it is nowadays not even possible to hypothesize the development of a product effectively without starting first from an in-depth analysis of the market and of the corporate strategy, less and less the strategic and information assets derived from these analyzes can be entrusted to an innovative development model based on the simple intuition or on the “mood” of the moment of a person or a group of people, no matter how good and prepared they are. It therefore becomes necessary to work on the development of systematic methodologies for innovation and problem solving. Over the years, some methodologies for Structured Problem Solving have been developed and established.

Axiomatic Design

Systematic design method that employs matrix methods to systematically analyze the transfer of consumer needs into functional requirements, functional characteristics that the product must possess to respond to customer needs, design parameters or the specific design parameters and finally process variables the process specifications necessary for the realization of the product.

The method, developed by Dr. Suh Nam Pyo at MIT in Boston, Department of Mechanical Engineering, takes its name from the use of “design axioms” that govern the decision-making process in the development of high-quality products or systems. The fundamental tool for the development of the method is the Design Structure Matrix (DSM, also called Dependency Structure Matrix or Problem Solving Matrix PSM), a square matrix representative of the system or project where the requirements (CTQs) are related in successive steps with functional requirements (FRs), functional requirements with design parameters (DPs) and design parameters with process variables (PVs).

According to the rules defined by the method, a form of the various PSMs is sought to maximize the effectiveness of the solution.

TRIZ methodology is often used for the solution of internal PSM problems.

TRIZ

TRIZ is the Russian acronym for Teoriya Resheniya Izobretatelskikh Zadatch, which can be translated into English as Theory for the Inventive Solution of Problems. It is at the same time a method and a set of tools developed in Russia starting in 1946 by Genrich Altshuller (1926-1998), with the aim of capturing the creative process in the technical and technological fields, codifying it and making it so repeatable and applicable. Altshuller’s approach to the study of creativity was an exquisitely experimental approach as he deduced from the study of the result of the inventive activity expressed in patents, the laws governing the evolution of technical systems. The architectural complex of TRIZ is based on the following observations: Technical systems evolve according to objective laws and tend to maximize their degree of ideality. Any specific technical problem can be traced back, through a process of abstraction, to a general model, and the logical processes of resolution can be grouped into a finite number of “solution principles”. Given the finite number of problem models and solving principles, conceptually analogous solutions can be applied to apparently different technical problems. Each technical system has characteristics that describe its state and determine its binding contradictions.

The study of these characteristics allows to avoid the compromises deriving from the contradictions, overcoming them, and obtaining high level solutions. Every technical system exists to release a main function. Over time, the functionality required of the system tends to persist while the solutions that allow it tend to change. In other words, someone, somewhere in the world, has already solved a problem “similar” to the one we are facing. On this conceptual basis Altshuller and his collaborators have built a set of tools that allow to: analyze a technical system and extract a model; apply the most effective solution principles to the problem model; search among the known solution models the ones most suitable for the analyzed problem.

More information on Structured Problem Solving methods:

-> http://en.wikipedia.org/wiki/Axiomatic_design

-> http://en.wikipedia.org/wiki/Dependency_Structure_Matrix

-> Using Dependency Models to Manage Complex Software Architecture

-> Altshuller Institute for TRIZ